Latest News

For the latest news updates please click here, or read on to learn more about Brunel's other bridge |

Introduction

The SWIVEL BRIDGE is Brunel's first large wrought iron opening bridge, it is far older than the Suspension Bridge, and is Bristol's only abandoned Brunel structure. The Bridge is listed Grade 2* and is on English Heritage's Buildings at Risk Register. The bridge rotates on four fixed wheels in contact with a solid ring under the bridge. The bridge was turned by a hydraulic mechanism of twin rams located in pits that are connected to a turning ring under the bridge via a substantial wire cable. The original turning mechanism prior to conversion to hydraulic machinery was a hand turned crank similar to that used on old train turntables. The pistons and chains are still in position. The original hydraulic system ran on fresh water supplied from a pressurised water system sited in Underfall Yard.Key historical points may be summarised as follows:

- The bridge was designed in 1849 by staff in I.K. Brunel's Westminster office to carry traffic over the new South Entrance Lock ('Brunel's Lock') in the Cumberland Basin, which was under construction at the time. The bridge became operational in October 1849.

- Brunel himself was closely involved in both its design and its construction. Represents an early stage in the development of the flanged plate girders that characterised Brunel's later medium span wrought-iron bridges.

- Brunel’s Swivel Bridge, which spanned the new lock, was fabricated at the Great Western Steamship works where the SS Great Britain had been built a few years earlier, and where the ship is now displayed in splendour.

- In 1872-1873 the bridge was shortened and relocated to its present position over the North Entrance Lock ('Howard's Lock').

- The hydraulic machinery of the lock was renewed in 1901-1902, manufactured by Sir W.G. Armstrong, Whitworth and Co Ltd of Newcastle upon Tyne.

- The bridge was decommissioned in 1968 after construction of the nearby Plimsoll Bridge as part of the new Cumberland Basin road system and it narrowly avoided being scrapped when the new bridge was constructed.

- Click here to see an animation of how it worked, created by Paco Lluna and his colleagues at Balfour Beatty.

Dimensions:

- The bridge is 110' 6" (33.7m) long overall

- the nose being 75' 6" (23.0m)

- the tail 35' 1" (10.7m)

- weighs approximately 68 tonnes without the timber deck.

- It is located on the man-made island at Howard’s Lock in the Cumberland Basin and rests in the open, swung position parallel to the dockside.

- The nose locates underneath the Plimsoll Bridge and when the Plimsoll Bridge swings open the clearance between the two bridges is as little as 4" over the starboard side girder.

The project has been supported by BIAS and AIBT for many years and is now supported by Bristol Civic Society and the Hotwells and Cliftonwood Community Association.

It is led by Geoff Wallis of Dorothea Restorations - jandgwallis@gmail.com

Videos

We have two videos showing some of the work so far. The first 'The New Wheel' is a film about casting the news wheel for the bridge, and the second is a summary of the restoration work so far. exhibition. This was intended originally to be shown without sound on a loop at a public exhibition. Click on the links to see the films on vimeo. Our thanks to Julian Baldwin for sharing them.The New Wheel www.vimeo.com/378113118

Summary Film www.vimeo.com/365737810

Brunel Swivel Bridge in 1906 |

1849 Tubular Bridge with wheels on circular track under the A370 Plimsoll Bridge. |

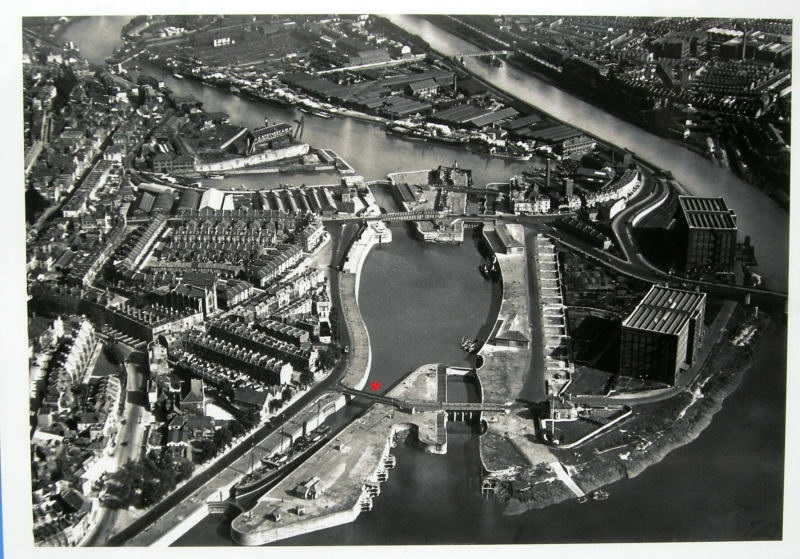

Aerial view |

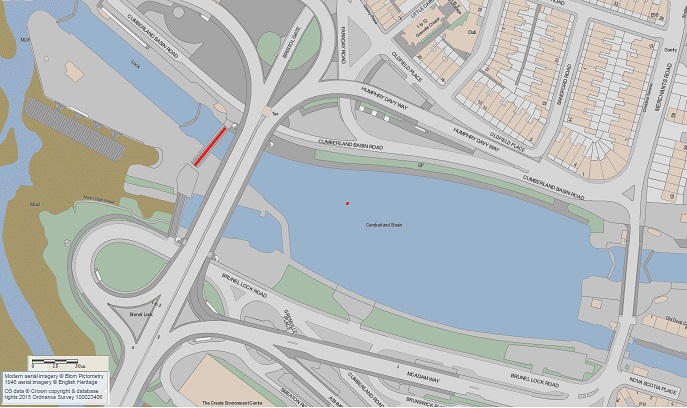

Map showing it crossing the lock! |

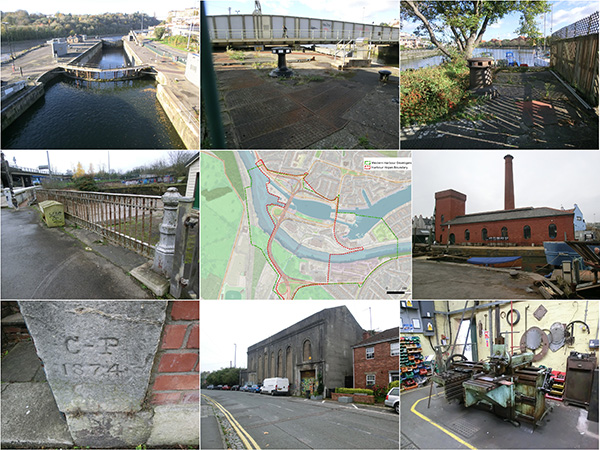

Bristol Western Harbour Heritage Assets

In 2021 a Bristol Civic Society working group was set up to identify heritage assets in the Western Harbour development area.Members: Geoff Wallis. Pauline Mousley. Julian Baldwin, and John Willis.

The information is presented on a web site which provides a location map, asset images, alternative names, history summary. and links to other information for each asset. The assets are indexed by name, alias, and map location.

bwhha.wordpress.com

There is a lot of useful information on the site but it is a work in progress. The group is currently reviewing and summarising the source documents and anticipate completing the web site later this year.

On this page

- Videos

- Rusting away

- Funding

- Leaflet

- Introduction

- 2023 Work and working days and Events

|

|

We are now on

Facebook! ![]()

We are now on

Twitter!

Rusting away

Investigative repairs to save the bridge were successfully done in January 2015 on the base of the beam. We need help to complete the project and stop the rot before it is too late. Rust on the beam |

Bucket of Rust under turntable |

Rust in the base of the beam |

PLEASE HELP US SAVE BRUNEL'S OTHER BRIDGE. WE HAVE GIVEN UP OUR TIME WILLINGLY TO SAVE THIS FORGOTTEN GRADE II* LISTED BRIDGE. PLEASE HELP US BY PROVIDING DONATIONS LARGE OR SMALL.

The latest estimated total costs of restoring the bridge and putting it back into commission is £1m and would take one year to complete.

You can send a cheque payable to

Bank details for bank transfer:

Funding received each year can be seen on the project reports for individual years

We have also created a project on http://www.neighbourly.com to also help us fund raise for our HLF bid

Workdays for 2025 as follows:

Avon Industrial Buildings Trust to:

The Treasurer,

24, The Bluebells, Bradley Stoke, Bristol BS32 8BE

Account name: Avon Industrial Buildings Trust

Account address: CAFCASH LTD

Kings Hill

West Malling

Kent ME19 4TA

Sort code: 40-52-40

Account number: 00006720

Historic England

We are very greatful for the support given through the years by Historic England by funding the investigative work. They are very keen to get this important grade II* Brunel bridge off the at risk register.

Bristol Visual and Environmental Group

As the treasurer of the BOB project, the AIBT would like to thank the Bristol Visual and Environmental Group for a donation of £10 000 in 2018 in memory of Dorothy Brown (we had already received £4000 in 2017). Dorothy was for many years an indefatigable champion of

the heritage in Bristol and its environs. Many historic buildings owe their continuing existence to the battles she fought for the heritage up to her death in 2013.

The organisation she founded, the Bristol Visual and Environmental Group, is now being wound up, and our project is very lucky to benefit from the residual funds being distributed from her trust by the surviving trustees.

Coop Community Fund

21 Sept 2016: The Brunel Swivel Bridge was selected to receive funding from the Co-op Local Community Fund. It meant that we got a contribution of £2,135.16 towards restoring the bridge.

Every time members choose Co-op branded products and services and use their Co-op Membership card (subject to Membership T and Cs)

1% of what they spend will go to their chosen cause. You can see the cause profile on the Coop membership website.

https://membership.coop.co.uk/causes/1505

Leaflet

Leaflet giving information, asking for support. To make a donation see the details above

2025

Please check the website for late changes.

Tasks for 2025

Can you help us with these tasks?

Email Geoff Wallis (jandgwallis@gmail.com) if you can help.

More 2025 details here

Brunel's Other Bridge

Brunel's Other Bridge