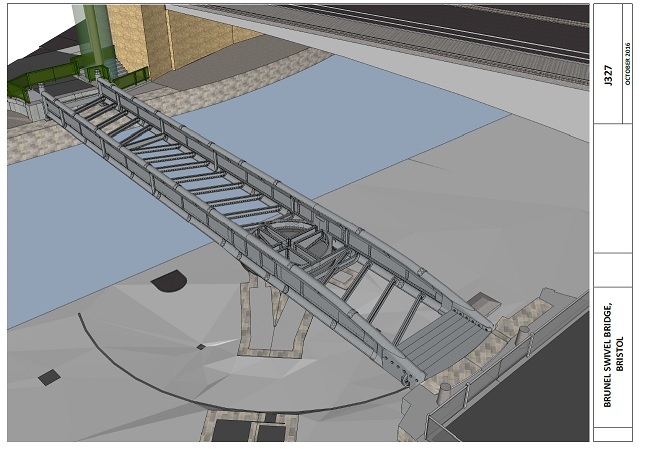

Brunel Swivel Bridge Project 2018

Investigative work on the rotation of the bridge 2018 |

Page contents

- Preparation and Basic Conservation

- Funding

- Progress in 2018 and details of work

- Photos of Progress in 2018

Preparation and Basic Conservation

Our aim this year is to complete the repair of the turntable mechanism to a condition in which it can again turn for trial-turning to be carried out. Our planned work is:- Continue with visitor surveying.

- Refit the SW wheel and its new bearings.

- Skim down the circumference of two wheels. (Two have already been remedied)

- Dress the wrought iron track under the moving structure to remove as much rust as possible.

- Make, deliver and fit a new steel-plate track under the existing one to provide a smooth running surface.

- Lower the deck back onto its turntable.

- Carry out turning trials and torque-tests.

- Rub-down and paint the outside of the little shed adjacent Brunel's Lock.

- Continue with general tidying, controlling weeds, removing litter, etc.

The track is an enormous wrought iron forging (about 14 ft diameter) probably made by rolling to a circle which must have been joined by fire-welding, ie, both ends being heated to bright-white heat and hammered together.

Excitingly we believe we have located the joint, evidenced by diagonal lines in the working face.

The forging is a complicated shape, remarkably accurate and a real tribute to the craftsmen who made it in 1849. We couldn't match this quality of manual forging nowadays.

It is an amazing example of heavy forge-work which should be preserved for future generations.

We plan to work one day per month, with extra days as necessary to maintain progress. We meet on the third or fourth Saturday in each month, as follows:

- Feb 17th.

- March 31st.

- April 21st.

- May 26th,

- June 23rd.

- July 21st.

- August 4th, 18th.

- September 15th. Doors Open Day.

- October 20th

Contact Geoff Wallis (jandgwallis@gmail.com) if you wish to help. We need to have an idea of numbers.

Funding

As you know, the Bridge is listed Grade 2* and is on Historic England (formerly English Heritage) Buildings at Risk Register. Whilst their funding is severely restricted, HE have been supportive in providing modest grants to carry out trials and erect a temporary roof, which were completed by Bristol City and Avon Industrial Buildings Trust with volunteer help last year.EH/HE were impressed with the Mann Williams (MW) report that resulted from the grant-funded work that we managed on behalf of the council in 2015 and suggested that we discuss an application for further investigative work on critical areas identified in the report as part of this year's Heritage at Risk programme. They also suggested that we might request further assistance in other areas via their consultancy budget and service.

- August 2018 I am pleased to tell you that the Trustees of the Bristol Visual and Environmental Buildings Trust have

agreed to contribute the sum of £10,000 for work to the turntable ring and a publicity event.

As the treasurer of the BOB project, the AIBT would like to thank the Bristol Visual and Environmental Group for a donation of £10 000 in memory of Dorothy Brown. Dorothy was for many years an indefatigable champion of the heritage in Bristol and its environs. Many historic buildings owe their continuing existence to the battles she fought for the heritage up to her death in 2013.

The organisation she founded, the Bristol Visual and Environmental Group, is now being wound up, and our project is very lucky to benefit from the residual funds being distributed from her trust by the surviving trustees. - 8 April 2017 The funding period for this project on the Coop Local Community Fund finished.

We have been awarded a total of £2,135.16

We were one of more than 4,000 causes across the UK who have benefited from the Local Community Fund and are making a difference in their communities. - 3 March 2017: I am pleased to tell you that the Trustees of the Bristol Visual and Environmental Buildings Trust have now

visited the Bridge on the last work day. Their report and observations have been most helpful.

The Trust has agreed to contribute the sum of £4,000 as match funding to Historic England's grant. - January 2017: £19,000 by Historic England for work to allow the deck to be rotated to establish what forces will be needed to turn it after it is fully restored.

- January 2017 £25,000 by Bristol City’s Central, Clifton and Harbourside Neighbourhood Partnership as match-funding for lottery funding

We want to thank Bristol City Council, English Heritage, the local amenity societies, our faithful hard-working volunteers, and huge number of supporters for getting the Project this far.

The big challenge lays ahead in securing major funding. We have a well-specified and costed scheme for repair which will form a sound basis for fund-raising.

You can make a donation using a charity website.

The main donation link now uses the Wonderful fundraising website:

https://www.wonderful.org/charity/avonindustrialbuildingstrust

https://www.wonderful.org/charity/avonindustrialbuildingstrust

mydonate will stop working in June 2019

We have created a project on http://www.neighbourly.com to also help us fund raise for our HLF bid

or you can send a cheque payable to

Avon Industrial Buildings Trust to:

The Treasurer, Thatched Wells, Duckhole,

Thornbury, BS35 1LD.

Leaflet giving information, asking for support and how to make a donation

Progress in 2018

October 2018

We meet on Saturday 20th October for our last workday this year, and hope to complete the refurbishment of the turntable wheels.Julian Beel and Bob Watkins will be leading the day as follows:

- We first free off the nuts on the bolts holding down the south-west and south-east bearings.

- Next we raise the outer plummer block of the SW wheel and clean rust off all the flat surfaces, and grease them to prevent rusting.

- The wheel will then be lowered and re-fixed on 14 mm of packings.

- Similarly, the south-east plummer blocks need to be raised, cleaned, greased, and packed up 17mm.

- The south wall of the little shed is now painted and the west wall primed. The west wall needs to be finish-coated, and if time permits the north wall can be rubbed down and primed.. Paint, brushes, scrapers, sand-paper etc, are on site, so all DIY-ers are welcome.

- More work is also needed to clear weeds, grass, moss etc, and generally tidy up around the Bridge. Please bring trowels, spades, buckets etc.

Youngsters are welcome provided their guardians are with them full time please.

Report Another useful workday, this time under the leadership of Bob Watkins and Julian Beel. Our seven stalwart volunteers included David, Maggie, enthusiastic and capable young Charlie, his dad Martin who continued painting the hut, and Julian Baldwin who videoed. Julian Beel borrowed gas bottles and heating torch kindly lent for the day by Dorothea Restorations and freed off the rusted nuts holding down the SE and SW bearings. The lads then rigged the special lifting gantry, raised the south west wheel and its heavy cast iron bearing, cleaned the underside, installed carefully measured packings, and reassembled the wheel/bearing assembly.

Our workdays this year have now ended for the year, but are due to resume next February when we hope to complete the levelling of the wheels and then turn our attention to centering and lowering the deck and fitting the new steel-plate track under the existing severely-corroded iron track.

May I thank each one of you for all your hard work this year, and both Dorothea Restorations and Ian Johnson the Docks Engineer for their support. We have achieved minor miracles, and next year hope to achieve a bigger one and be able to rotate the Bridge again, 160 years after its completion in 1849.

Photos of Progress October 2018

September 2018

Doors Open Days Brunel Swivel Bridge went well with rather more than 100 recorded visitors on Saturday only, and a number of new volunteers have promised to join us. Our welcomers and guides were Mary Stacey, Rob Isles, Bernard Roberts, Keith and Jenny Hickman, Paul Wood, and David Greenfield. On display we had three separate sets of photographic boards, a table of artefacts, the giant pattern of the new turntable wheel, an early bronze bearing, and the huge spanner with which we tried unsuccessfully to unscrew the giant central Brunel Bolt. Our visitors really enjoyed themselves, so well done everyone!Practical work was carried out by Martin, his fifteen-year old son Charlie, and Geoff. Martin sanded and painted the west wall of Building 149, the little shed beside Brunel Lock, whilst Charlie led the task of setting up the gantry and chain-hoist, releasing and raising a 300Kg wheel, cleaning off rust (a difficult, messy job) and reassembling everything on new packers. Well done Charlie, not bad for a fiteen year-old!

Keep an eye on our web-site for the October workday, and join us then.

August 2018

Our next volunteer workday is this coming Saturday 18th August, and the weather forcast is reasonably good so we plan to make progress on the following:- We have the new bronze bearings now for the south east wheel, so we'll fit those and wrestle the wheel into place. It came out with only 6mm to spare, so it may be a challenge to get back in!

- Then we need to check whether that wheel, and the SW wheel which we fitted last time, are at the same height as the two northerly wheels, so Bob plans to do some surveying. We shall have packings to fit under the SW bearing, so after checking levels we'll fit these if time allows.

- We have needlegunned and painted the underside of the old turntable track in readiness for the new steel track, but we need to apply another coat of 'high-tech' two-pack paint. Its an easy job but needs care to ensure we achieve an even, thick coating.

- The central pintle bearing still needs more work to it, including finishing off radiussing the hole into which the new brass collar fits.

- We need to put a finish coat on the outside of the little shed. We have done most of the hard work and the south wall is beginning to look good. Paint, brushes, scrapers, sand-paper etc, are on site, so all DIY-ers are welcome.

- Thanks to those who 'gardened' last month. Weeds are becoming established in the parapet of Jessops old lock so we need to clear them before they do damage. More work is also needed to clear weeds, grass, moss etc, and generally tidy up around BOB. Please bring trowels, spades, buckets etc.

- Everyone in our regular team works so hard, that visitors to the site often don't get a proper welcome and explanation about the project. Could you 'meet and greet' visitors and give a brief outline on the Bridge's history and our restoration project? We'll brief you, and your help will be very welcome.

Report

Photos of Progress Aug 2018 .

Despite being deep into holiday period a good number of stalwart volunteers turned out today, thank you folks. David, Julian Beel and Geoff installed the south east wheel and its bearings,

which required a fair amount of dressing of the new bronze bearing-castings to make them fit their cast iron plummer blocks (pedistals) Bob and Martyn then checked and rechecked the levels of the wheel-crowns

using a very accurate engineer's level. Next time we shall have to raise the three wheels that are slightly low and insert some packings.

Thanks Julian Baldwin for videoing and helping out generally, and Maggie for pressing on with the undercoat on the south wall of the shed, which is now ready for its top-coat. Many thanks Maggie and Mike for fitting a new backing board to both the interpretation panels, with very neat results.

Bob Watkins and Geoff were minding their own business surveying levels on the turn-table wheels one afternoon recently when a Prof Felix Schmid, PhD, FIMechE, FIRSE, FPWI from the Birmingham Centre for Railway Research and Education at the University of Birmingham turned up unexpectedly with nine students. They were walking the docks but apparently didn't know of the Swivel Bridge, so Bob and Geoff gave them an impromptu tour of the Bridge and lifted the pit covers for them to view the hydraulic rams. Brunel's design of the turning gear generated some lively discussion about the great man's 'abilities' as a mechanical engineer, and the extraordinary achievements of the metalworkers who actually constructed the Bridge. The visitors left inspired by a new understanding of what wrought iron is, and the remarkable structure surviving in the City Docks.

Next session is Bristol 'Doors Open Day' on 15th September so do come and help us then.

We send our very best wishes to Martyn Hart who is relocating to Baldock in Hertfordshire. Thank you for all you have contributed over the years as a hard-working volunteer and as a valued member of our technical team. We'll keep you in touch via our extensive e-mail network, and hope you will come back and visit us occasionally.

4 August

There are some additional tasks to carry out on the wheels now so we are holding TWO workdays in August, on Saturdays 4th and 18th. We need to make good progress whilst the dry weather holds, and the

two dates will give those of us on holiday a second chance to help out!

The next workday is therefore at the end of next week, 4th, when we plan to fit BOTH the south wheels, trial-fit the central collar, and progress the painting. It would be really helpful if one volunteer could please 'meet and greet' visitors as it engages them and avoids those working on other tasks from being distracted.

We'll start at 9.30 am to make best use of the day. There is plenty of parking space and basic toilets are available. Please wear stout footwear, and you might like to bring overalls, gloves and something to kneel on. We have gloves, high-vis vest and a helmet for you to borrow, and we provide tea and coffee!

Youngsters are welcome provided their guardians are in attendance full time please.

Looking forward to seeing you on Saturday 4th.

Report 4 August

By 10.00 today we had the last 250Kg wheel out of Geoff's gropaning estate car, which could be heard sighing with relief! By 12.00 Bob, Geoff and Julian Baldwin had trundled the wheel to the centre of the

Bridge on rollers, Egyptian pyramid-style, (but without the slaves) and lowered it into place below the deck. Meanwhile Julian Beel freed off the nuts holding down the bearing of the south west wheel,

aligned it and settled it down on its new bronzes. The caps were refitted and the level checked against the adjoining north east bearing. It was about 5mm low so we'll prepare 5mm of copper packing to fit

under the bronze shortly.

Ian helped with the wheel-move and then took on preparing the south east bronzes for installation. Julian and Geoff trial-fitted the newly-made collar bearing, and Julian took on the unpleasant task of sanding the rusty cast iron pintle clean, laying on his side in the pit under the Bridge(see July photos).

We were pleased to welcome young Bailey back again with his mum Anne. Bailey helped out with many tasks and finally fitted the new nuts on Julian's bearing using a giant spanner.

Photos of Progress Aug 2018 Well done everyone. See you on 18th August.

July 2018

Our next volunteer workday is next Saturday 21st July. We have lots of important items to progress as follows:- Julian Beel is leading the refitting of the south west wheel and needs help fitting the new bearing bronzes.

- We have needlegunned and painted the underside of the old turntable track in readiness for the new steel track, but we need to apply another coat of 'high-tech' two-pack paint. Its an easy job but needs care to ensure we achieve an even, thick coating.

- Our two information boards are very popular, but their plywood backings have rotted, as you can see in the photo attached. Can anyone please take these boards away and replace their backing?

- We need to put another undercoat and finish coat on the outside of the nearby little shed. We have paint, brushes, scrapers, sand-paper etc, so all DIY-ers are welcome.

- Thanks to those who 'gardened' last month. Weeds are becoming established in the parapet of Jessops old lock so we need to clear them before they do damage. More work is also needed to clear weeds, grass, moss etc, and generally tidy up. Please bring trowels, spades, buckets etc.

- The newly-refurbished wheels have become scuffed, so we need to make good to the paintwork.

- Everyone in our regular team works so hard, that visitors to the site don't get a proper welcome and explanation about the project, and this will worsen when we take the boards away temporaily. Are there any helpers who could take on the role of 'meeter and greeter' to welcome visitors and give a brief outline on the Bridge's history and our restoration project? Your help will be very welcome.

Youngsters are welcome provided their guardians are in attendance full time please.

Report

21 July was a very productive (and fun) work-day, photos of which can be seen on the website.

An intense and hot but very productive day today with all our most expert volunteers working at full tilt. Julian (Beel) and his team worked hard to fit the four lovely new bronze shells to the south west

wheel's plummer blocks (those are the big cast iron chairs the bearings sit in). These fitted well but we have now discovered a slight misalignment between the two blocks, so next time we must free off

the 'plummer blocks' which support the bronzes and realign them. This realignment is important because each wheel can potentially take many tonnes weight, and once the Bridge is back down on its turntable

we can't get at the bearings!.

Chris Eade and his team fitted the new cast bronze ring around the central pintle around which the entire Bridge rotates. Chris valiantly sanded off the rust from the corroded pintle laying on his back under the Bridge, an unpleasant, dirty, dusty, noisy job. Well done Chris, and thank you (see photos). We proved that the new ring will fit, but Geoff has to dress away some excess material, and Chris will drill and tap holes for grease-nipples to be fitted so that we can lubricate the new collar in the future.

Ian and Geoff reclaimed the threads of the rusty holding-down bolts on the NW plummer blocks using our giant new die-nut, and then fitted enormous new nuts. These are 1 1/4 British Standard Whitworth nuts, with a thread developed by Joseph Whitworth in 1841, just eight years before Brunel designed the Swivel Bridge.

Maggie continued the visitor survey, weeded, and photographed, whilst Bob W, David F and Geoff W helped as necessary on the main tasks, whilst Julian Baldwin captured some good, professional-standard, video footage.

We were delighted to welcome the Kay family. 15 year old Charlie is expert at rigging the hoisting equipment now and had the 250Kg SW wheel raised in no time. Then he helped with all the aforementioned tasks, and was soon joined by his mum Polly and younger sister Daisy. Daisy was keen to prove that she could get into the cramped main structural boxes of the Bridge just as Charlie had done when he first visited site three years ago. Charlie has grown far too big to fit through the narrow entrance gap now, but Daisy managed it. However, Charlie then refitted the cover and stood on it, trapping her inside! (Big brotherly love!). Daisy was soon released no worse for her experience, see photos. We'll find a new space for you to climb into one day Charlie.

Charlie's Dad, Martin heroically sanded off the hut's Canary Yellow paint, a hot, dusty job which turned Martin bright yellow for a while! He and Daisy then applied more (white) paint and the south side of the shed now looks really smart.

As the weather is stable and there is so much to do we are holding two volunteer workdays in August, on Saturday 4th and 18th, starting at 9.30am. Do come and join us if you can.

June 2018

We are meeting next Saturday (23rd June) to continue our work on the Bridge, as follows:- Julian Beel is leading the refitting of the south west wheel and needs help fitting the new bearing bronzes. Thanks for preparing the bronzes Julian.

- We have needlegunned the underside of the old turntable track in readiness for the new steel track, but we need to clean out rust in the pits and give it a coat of 'high-tech' two-pack paint. We have a high-speed burr to clean into the pits and a power-sander for the flat surfaces, but we need to at least two volunteers to operate them please. Thanks David and Ian for your heroic work last month.

- When the Bridge was in service the north west turntable wheel wore badly and was packed up to compensate for the wear. We have fitted a new wheel, so the old packers now need to be removed. Our friends at Dorothea have lent us some heating equipment, so come and join us as we lift the wheel, heat the rusty nuts and pull out the packers.

- Last month Martin did some superb work preparing and painting the outside of the nearby little white shed, and it is looking good, but we need top get a top-coat onto the south wall, carry on preparing the other walls and get a coat of primer on them. We have the paint, brushes, scrapers, sand-paper etc, so all DIY-ers are welcome.

- Thanks to those who 'gardened' last month. More work is needed to clear weeds, grass, moss etc, and generally tidy up. Please bring trowels, spades, buckets etc.

- Sal and Maggie need help with our survey of members of the public crossing the site. Its an interesting job that enables us to talk to visitors and canvass support.

On a sweltering day we were happy to hide in the shade under the Bridge and beaver away at two main tasks. Out structural engineer Bob checked how much the new north-west turntable wheel stood above its neighbours, having been renewed with a new full-size casting. It stood 20 mm too high as the original had worn and its supports had been raised on steel packers. Julian, Ian and Bob used a gas-torch borrowed from our friends at Dorothea Restorations to free off the rusted nuts holding down the bearings, lifted the wheel with the chain -hoist and extracted all the packers. (photo attached). They cleaned out under the bearings, lowered the assembly and found that the wheel then levelled accross well with its neighbours.

Meanwhile Geoff was getting thoroughly dirty sanding rust off the turntable track-ring in readiness for painting. To everyone's amusement he emerged unrecognizably black, see photo. Maggie surveyed visitors, photographed and generally tidied up and swept out the base to assist those working in it.

Ian and Geoff finished off the day by painting half the little hut's south wall bright yellow, until beaten by the unrelenting heat of the scorching afternoon sun. Its not often one can say that in England!

Photos of Progress June 2018

May 2018

Workday We next meet on Saturday 26th May to continue our work on the Bridge, as follows:- Julian Beel is leading the refitting of the south west wheel and needs help dressing and fitting the new bearing bronzes.

- We need to de-rust and paint the underside of the old turntable track in readiness for the new steel track. We have a clever electric descaler but we need at least two volunteers to use it.

- We have started re-painting the outside of the nearby little white shed, and it is starting to look much less scruffy already. We have the paint, brushes, scrapers, sand-paper etc, so all DIY-ers are welcome.

- Summer is upon us and the vegetation is growing well under and around the Bridge, so gardeners are needed to clear weeds, grass, moss etc, and generally tidy up. Please bring trowels, spades, buckets etc.

- Finally we need to continue our survey of members of the public crossing the site, so Sal would appreciate some help filling in the simple sheets.

Youngsters are welcome provided their guardians are in attendance full time please.

Report: A misty day.

Recently we have made good progress towards recommissioning the turntable wheels as we work towards getting the Bridge rotating again. Two new bronze bearings and a huge bronze ring have been delivered by a local foundry (see photo) and these will shortly be going off to our friends at Croft Engineering for machining.

On the May Bank Holiday Saturday nine faithful volunteers completed some useful tasks. Ian and David heroically laid on their backs and took it in turns to needle-gun rust off the underside of the turntable, an unpleasant, arm-aching task that dropped rust in their faces. They did the job to a high standard so that in June we can complete the detailing and put on a coat of paint. Well done chaps, and thank you again.

14 year old Charlie is now so expert at rigging and operating the chain-hoist (under supervision) that he had the south-west wheel lifted clear of its bearings in no time, and then Julian Beel used his considerable skills as a grinder-artist to sculpt its new bronzes to fit their cast iron beds. Charlie then moved on to investigating and cleaning the control-pits, and removing the tarmac obstructing the tail-wheel track. To our surprise this revealed a 25mm step at a joint in the track, so we now have more work to do! Meanwhile Charlie's dad Martin expertly prepared and painted the south side of the little shed with professional results.

Maggie surveyed, photoed and weeded with Martyn, whilst Julian Baldwin videoed, and Geoff helped out generally. Thank you all for your hard work. See you on 23rd June.

Photos of Progress May 2018

April 2018

We meet again next Saturday 21 April to continue our work on the Bridge, as follows:- The north-east wheel has recently been machined by Croft Engineering in Fishponds, and I plan to bring it along for fitting. We need to remove the original bronze bearing shells, clean them, fit some copper packers, and then re-fit the wheel. As last time, please bring your wedges, jemmies, crow-bars, etc to help persuade the bronzes out of their housings.

- The south west wheel is also ready to fit, but we need to realign the plummer block first. These are the big cast iron seatings that house and support the bronzes, so one team will attend to this whilst another fits the NE wheel.

- If anyone prefers to paint, (or if too many vols arrive) the Dock Engineer has given us permission to repaint the outside of the little white shed, so all DIY-ers are welcome

- We need to continue our survey of members of the public crossing the site, so Sal would appreciate some help filling in the simple sheets.

- Finally, spring has sprung and the vegetation has started growing, so gardeners are welcome to clear weeds, grass, moss etc, and generally tidy up. Please bring trowels, spades, buckets etc.

Youngsters are welcome provided their guardians are in attendance full time please.

A lovely warm day brought out lots of volunteers, and renewed enthusiasm for getting Mr. B's Bridge turning again. We welcomed a newcomer Jeff, all the way from Cambridge, welcome.

Bob's team including David, Martyn, Charlie and Jeff rigged the lifting gear whilst Geoff's team lifted off the bearing caps on the north east bearing, levered out the bottom bronzes and thoroughly cleaned everything. The recently skimmed 300 Kg wheel was hoisted out of Geoff's car and onto its frame, trundled along the Youngman's board track and lowered into place effortlessly, due in no small measure to young Charlie who led much of this operation himself. Well done Charlie, you are a remarkably mature and practical engineer for your age.

Meanwhile Charlie's dad Martin was turning 'shabby-shed' into 'shabby-chic' by scraping off loose paint, patch-priming the bare wood and undercoating between the rain storms. Martin was ably assisted by Maggie, Anne and young Bailey in his wonderful new red mini-coveralls, red hard hat, red socks and high-tech gloves. Shed 149 has started to look more cared for now, thanks to your hard work.

Julian Beel borrowed his employer's gas-cutting equipment (thank you Dorothea) and freed up the bolts securing one of the SW wheel's bearing blocks. He realigned it and re-tightened the nuts, so that we are now ready to fit the bearings during the May vols day.

Thanks for photographing and doing some survey work Maggie, disrupted eventually by the Portway being closed, and thank you Julian Baldwin for videoing us again.

At the end of the day we placed a straight-edge across the tops of the NW & NE wheels and found 15 mm difference, so now we'll have to seek the reason for this misalignment, which appears to have been long-standing. Just the latest mystery!

Come and join us on 26th May, the week after the royal wedding.

March 2018

Sat 31 March. Our next workday is nearly upon us, and there's lots to do:- The south-east wheel has recently been machined, see photo attached showing our wheel in a giant lathe at Croft Engineering in Fishponds, with machinist Paul Tyrer. Before we can fit it we need to remove the original bronze bearing shells, clean them, and adjust one to fit the skimmed journal, so our trusty team of bearing-wrestlers with wedges and jemmies is needed again please. I have a cunning idea to help us pull out the shells this time!

- The next, and final wheel, needs to be lifted out of its bearings, trundled along the deck and loaded to my long-suffering estate for delivery to Croft Engineering who will skim off the flange worn on the outer circumference. We are getting quite slick at doing this, but we need YOUR help as we also have to chip off rust and 'many hands make light work'. We may have a descaling machine at our disposal this time.

- If anyone prefers to paint, (or if too many vols arrive) the Dock Engineer has given us permission to repaint the outside of the little white shed, so all DIY-ers are welcome

- We need to continue our survey of members of the public crossing the site, so Sal would appreciate some filling in the simple sheets.

- Finally, spring has sprung and the vegetation has started growing, so gardeners are welcome to clear weeds, grass, moss etc, and generally tidy up. Please bring trowels, spades, buckets etc.

Meanwhile, Maggie, Julian Beel and Geoff persuaded the bronzes out of their housings on the south east wheel's bearing blocks so that they can be cleaned and dressed to fit the skimmed wheel-shaft. Julian Baldwin was on hand to video this stage of the work. By the way, Julian recently entered his video of the manufacture of the new NW wheel into an international competition and did well, so congratulations Julian.

Finally, Ian Kerr unveiled his Meccano and polystyrene model of the 'setting gear' which sets the Bridge deck at the correct level on the north bank of the Entrance Lock. (See this months photo). Ian has made and exhibited a giant Meccano model of the Swivel Bridge, so the setting gear completes the model.

We should have two wheels ready to re-fit next workday, so do come and join us on 21st April.

Photos of Progress in March 2018

February 2018

Our first workday of 2018 is on Saturday 17th Feb. when we have lots of interesting tasks to carry out.- Sal is away, so we need a volunteer to continue her survey of members of the public crossing the site, for which a sheet is available to fill in.

- The south-west wheel and its shiny new bronze bearings are complete and ready to refit, so we need to erect our gantry, hoist the wheel from its delivery-vehicle, raise it to deck-level, trundle it to the center of the Bridge and lower it into place. Then the next wheel needs to be hoisted out and loaded so that it can go to a local machinist for skimming. They are waiting for it, so we need to extract it asap. We are getting quite slick at doing this, but we need YOUR help as many hands make light work.

- If anyone prefers to paint, (or if too many vols arrive) the Dock Engineer has given us permission to repaint the outside of the little white shed, so all DIY-ers are welcome.

- Finally, spring is nearly upon us and the vegetation has started growing, so gardeners are welcome to clear weeds, grass, moss etc, and generally tidy up.

Bob W, David F, Maggie S, Geoff W and new expert volunteer Julian Beel enjoyed working together in lovely February sun, videoed by our professional-standard media-man Julian.

Our first aim was to install the newly machined 300 Kg.wheel delivered to site in Geoff's long-suffering down-at-the rear estate car.

We did this with ease, using our shiny new steel gantry which sits over each wheel-position and provides a 'sky hook' for us to hoist from.

Our new young volunteer Bradley helped operate the chain hoist, spread grease on the bearings for protection and other tasks, supervised by mum Anne.

Thank you guys, your help was appreciated. You'll make a great engineer one day Bradley!

We then turned our attention to the south east wheel which wasn't so easy to extract as the headroom is lower. We had to do a 'fox-trot' move by lifting the wheel, rotating it laterally, moving it sideways, and then lifting it

out. Fortunately there was about 10mm to spare, but it was fiddly working under the bridge.

We have become experts now at moving the wheels along the deck on their frames using rollers, and can even go up and down a step.

Bob, David and Geoff had a think about how to strengthen the severely corroded beams that carry the weight of the deck above the turntable.

We decided that a series of oak 'pit-props' was the best solution, tightened by folding wedges. Finally we laid down under the structure, and brainstormed a way of centralizing the deck using new bronze bearing blocks,

so now we have lots of work to get on with this year. Come and help us!'

Photos of Progress in February 2018

Look at the reports page to see the summaries of the results of inspections of the bridge. Updated 11 January 2016

Photos of Progress in 2018

- Photos of Progress October 2018

- Photos of Progress Sep 2018

- Photos of Progress Aug 2018

- Photos of Progress July 2018

- Photos of Progress June 2018

- Photos of Progress May 2018

- Photos of Progress April 2018

- Photos of Progress March 2018

- Photos of Progress February 2018

Brunel's Other Bridge

Brunel's Other Bridge